The auxiliary mechanism is equipped with various practical parts that can be selected in accordance with the desires of the user, which includes a worktable compensation mechanism, a backgauge, A fast-release die clamping device, a cloth provider, an oil temperature Regulate system that can interesting or warmth the oil, a photoelectric defense product, a centralized lubrication system, and even more.

Sheet metal bending approaches are very similar in that their close goal is to rework metal constructions into the specified sorts. However, they differ in operation.

Most back again gauge systems incorporate a swing-up or retractable style. This aspect lets the gauges to rotate upwards or retract when essential, avoiding potential collisions with the sheet metal in the bending system.

A press brake is a piece of producing equipment that is utilized to bend sheet metal. It is usually narrow and prolonged so that giant items of sheet metal might be bent by it. Press brakes complete these bends by clamping the sheet or plate involving the movable punch and the stationary die.

Because of the confined attain on the arm to the tip from the tank, a towel might be wrapped about a bamboo or stick with clean the corners. The leaking plug or brake valve really should be loosened to enable the dirty oil to empty.

If alignment problems persist, a radical inspection from the ram’s floor ailment and guidebook system is necessary, with opportunity adjustments to the Y axis as essential.

It is another essential element of sheet metal bending structure. The k-variable characterizes distinctive bent sheet metal geometry and really helps to determine other style variables like needed allowance. The K-aspect is described because of the “Ratio of size which the neutral axis shifted from the first position to sheet thickness.

Creating the Brake Press: We make use of a machine called a brake more info press, which creates the bends. The metal sheet is placed between a punch plus a die established. The punch pushes to the metal, bending it over the die.

Nonetheless, they have confined tonnage capacity and less overall flexibility in stroke adjustment when compared to hydraulic systems.

Advanced press brakes may integrate features like computerized tool changers, robotic content managing systems, and actual-time bend angle measurement for Increased efficiency and top quality Manage.

The different types of press brakes also have different speeds and accuracies at the same time. A servo electric press brake will commonly have the best diploma of accuracy. Pneumatic and servo electric powered press brakes help you save time because they are usually a lot quicker than hydraulic and mechanical brakes as well.

The punch is usually a good substance that is definitely reduced down onto the metal. For the reason that pressing action from the punch on to the metal plus the die are what triggers the metal to bend, both of those shapes have to be correctly suited towards the bending work.

The hydraulic oil employed need to be clear. To fill the oil, unscrew the nut of your air filter and fill in the filter. If working with filling equipment using a filter, the quilt on the oil tank may be opened as well as the oil may be stuffed directly.

These cookies are important to the Main operation our Internet site and several of its attributes, such as entry to safe spots.

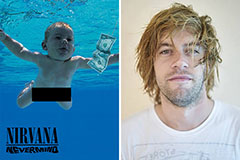

Spencer Elden Then & Now!

Spencer Elden Then & Now! Alicia Silverstone Then & Now!

Alicia Silverstone Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now!